Description

THE PRO STANDARD.

Icons are made through the pursuit of perfection, and with the introduction of our Type-X™ PRO, we are yet again redefining the auxiliary driving lights as we know it. A design that began with a single line on a piece of paper, iteration after iteration resulted in an emblem that represents our commitment to producing category defining products. Our PRO edition epitomises our commitment to maximising light output and reliability at levels that surpass the most respected players in the industry.

A WOLF IN WOLF’S CLOTHING.

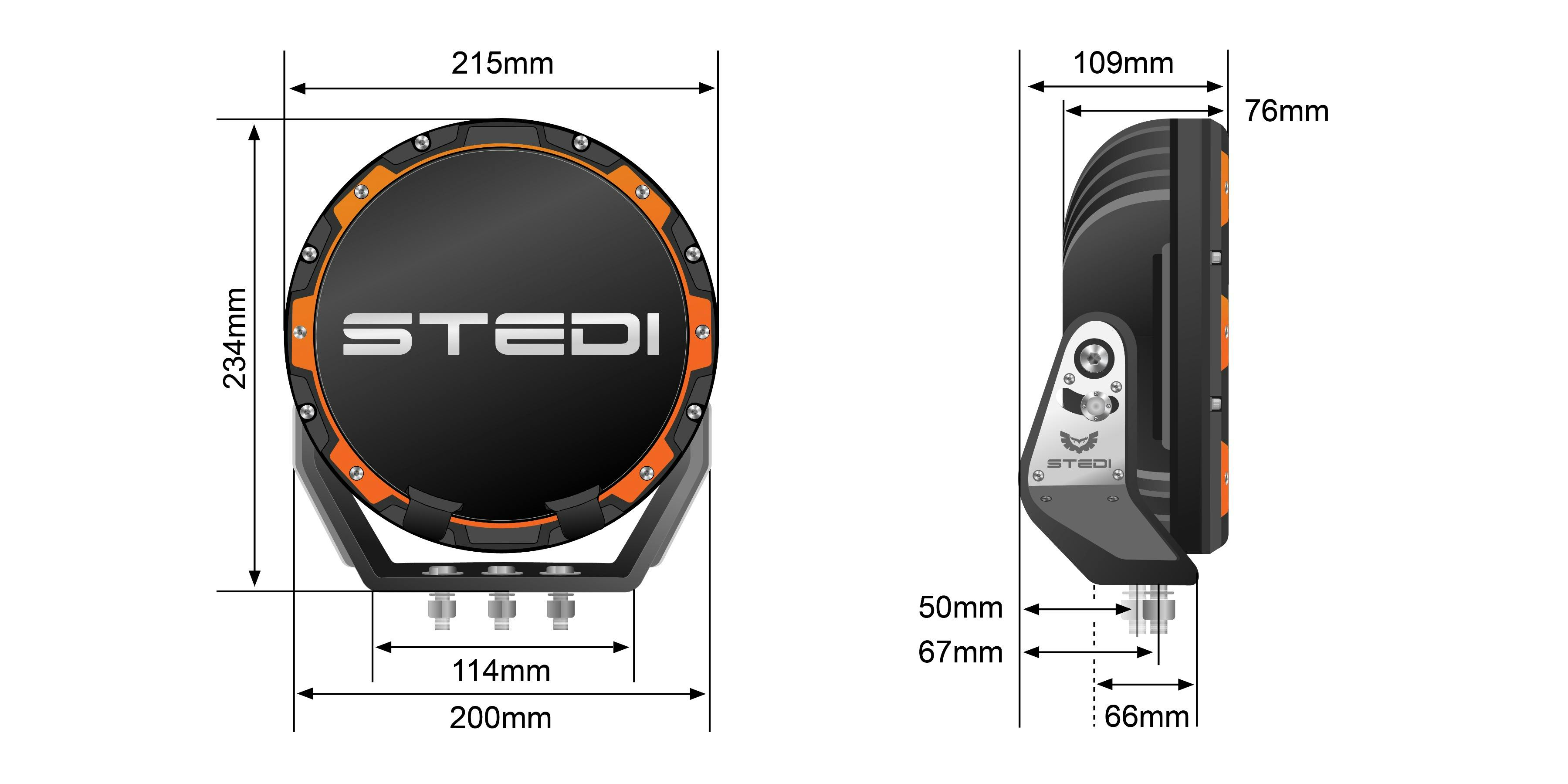

Forget folded steel brackets, it’s all yesterday’s news. The Type-X™ PRO is all about pushing boundaries. The bracket system is a 10mm thick high-pressure die-cast aluminum marvel of engineering. Our Type-X™ PRO bracket was designed to withstand extreme and prolonged corrugations time and time again. While they were designing for speed of production & cost efficiency, true to STEDI’s signature design principles, we added layers of complexity and additional assembly operations. Now, just imagine the lengths we went to with the optics.

1.15KM BEAM THROW.

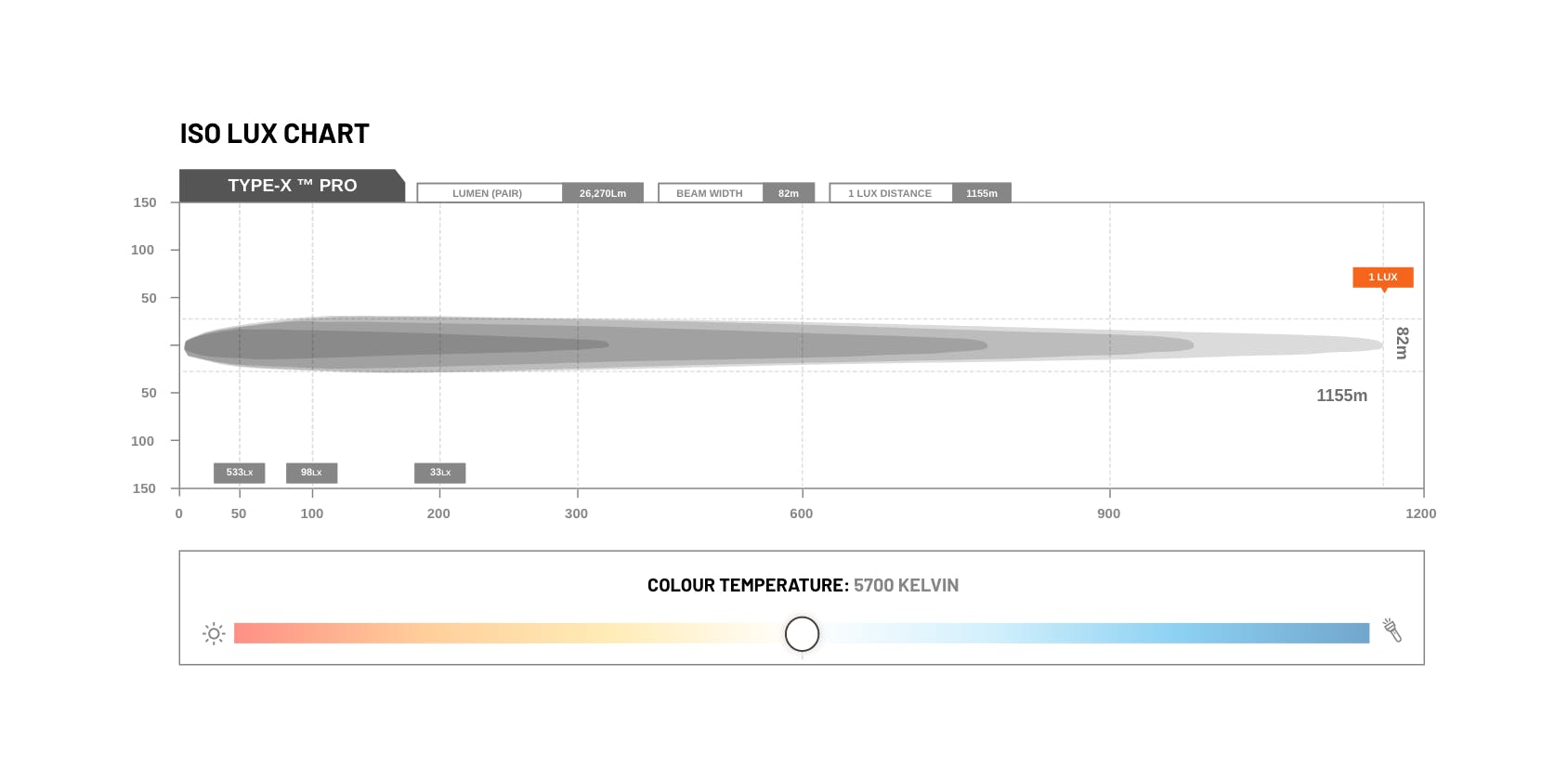

Using the latest optic simulation modeling, the reflector geometry was tweaked over and over again to achieve a highly-functional beam pattern. An astonishing beam throw coupled with a homogeneous wide beam, will have you insist on driving only when the sun’s down.

THE NITTY

GRITTY.

ALWAYS ON THE CUTTING EDGE.

Cutting edge performance starts with cutting edge LED technology. To achieve genuine category-leading performance our Type-X™ Pro is equipped with 37 x Oslon High-Flux LEDs, selected for having the #1 highest lumen density per mm2 of any other comparable LED on the market. Compared to the two other leading spotlights brands similar offerings, the LEDs used in Type-X™ PRO have + 23% and +42% higher lumen density per mm2 in comparison. The net result is higher net light volume and unrivaled beam throw.

A WOLF IN WOLFS CLOTHING

The hard-coated optical grade lens shares the same DNA as ballistic glass making it virtually indestructible. A UV stabiliser has also been added to ensure our lenses truly withstand the test of time with no discolouring or UV degradation. This has allowed us to do away with any secondary lens covers or filters which are known to significantly reduce light transmission.

ICONIC PERFORMANCE

Using the latest optic simulation modeling, the reflector geometry was tweaked over and over again to achieve a highly usable beam pattern. No doubt the attention grabber is the unrelenting beam distance of 1,155m (tested in pairs, combo beam), however, the real strength of our Type-X™ PRO is in mid to long light distribution that really sets it apart.

Our key focus was on driver confidence, by increasing the beam throw the driver has longer analysis time. We maximised driver comfort by smoothing out the beam eliminating shadows. We reduced the light wasted in unimportant zones like treetops and immediately in front of the vehicle. The result is a homogeneous, unrelenting beam that will support you well in any adventure.

Unlike our competitors, each Type-X™ PRO lamp has 6 built-in flood reflectors for improved light distribution out into the road shoulders. The built-in wide-beam reflector eliminates the need to add any wide beam covers, which are not only less efficient at distributing light, covers also withhold valuable light transmission.

(Registered Design Number 201814836 & Registered Trademark).

TECH SPECS

| LED | 37 x Oslon High-Flux LED |

| RAW LUMENS | 26,270 (Pair) |

| TESTED LUMENS | 15,870 (Pair) |

| AMP DRAW | 10.4A @ 13.2v (each) |

| POWER DRAW | 137W |

| CANDELA | 1,334,025cd |

| BEAM PATTERN | 6 x 50° Spread

31 x 5.8° Pencil Beam |

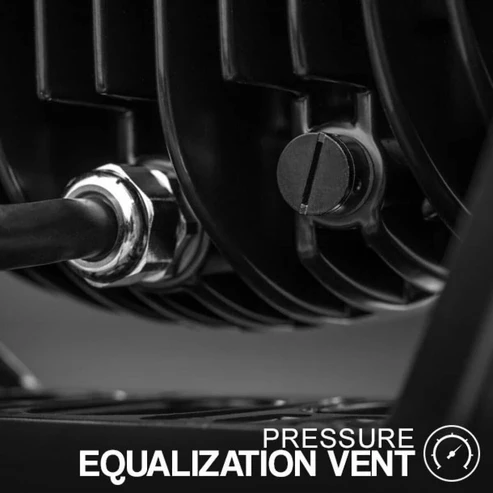

| INGRESS PROTECTION | IP68 | Submersible up to 3m |

| COLOUR TEMP (CCT) | 5700K |

| VOLTAGE COMPATIBILITY | 12v & 24v |

| LUMEN MAINTENANCE | 50,000 LM-80 |

| WEIGHT | 2.860kg (each) |

| OPERATING TEMPERATURE | -40°C to 60°C |

| PHOTOMETRIC DATA | |

| 10 m | 13,340 Lx |

| 50 m | 533 Lx |

| 200 m | 33 Lx |

| 300 m | 14 Lx |

| 400 m | 8 Lx |

| 1,000 m | 1.3 Lx |

| 1,155 m | 1 Lx |

WHAT’S INCLUDED

- 2 x STEDI Type-X PRO LED Driving Lights

- 2 x Protective STEDI Black Out Covers

- 2 x Grey Colour Rings

- 2 x Orange Coloured Rings

- 1 x Smart High Beam Wiring Harness DTP-2 Sealed Connectors, H4, HB3 adapter plugs to high beam. 60A Relay, Fuse, Switch

- Complete Stainless Steel fastener kit.

- Wiring & Fitting Instructions