Description

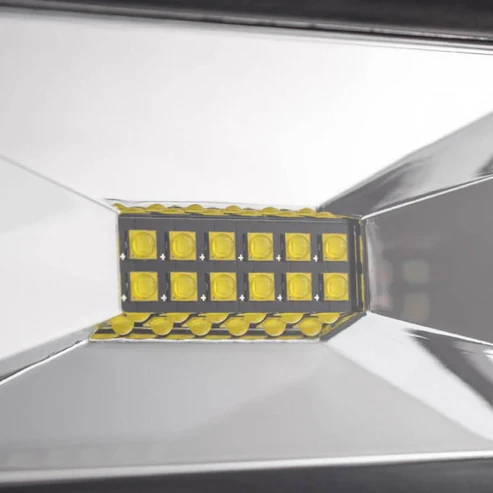

The MCG called, they want their lights back. STEDI’s all new 14 inch 120W Hyper Flood LED make for the ideal flood light for camping, agricultural or mining machines. The super wide 120 degree beam angle provides incredible coverage unmatched by anything else that is currently on the market. The beam is not only wide it’s also unbelievably smooth, which provides outstanding clarity.

120 DEGREE FLOOD HYPER FLOOD BEAM 120W

DETAILS

- Hardened Steel U Bracket

- 5 Watt CREE LED

- Optical Hardened PC Lens

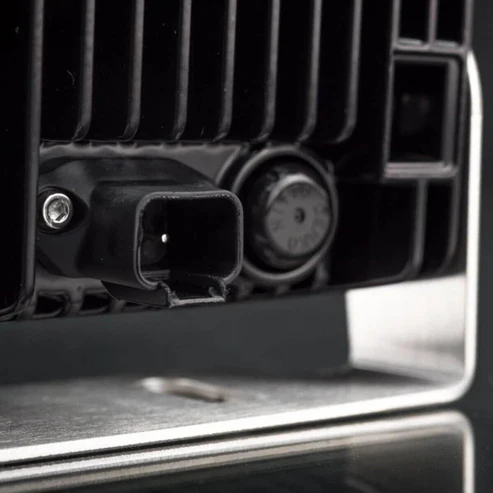

- Environmentally Sealed Deutsch DT2 Connectors

- 24 Month Warranty

Price quoted is for 1 unit.

SPECIFICATIONS

| POWER | 120 Watts |

| LED CHIP | 5W Watt High Intensity CREE |

| CURRENT DRAW | 6.8A @ 13.8v, 2.9A @ 24v |

| VOLTAGE | 9 to 32v |

| RAW LUMENS | 10,800LM |

| INGRESS PROTECTION | IP67 |

| COLOUR TEMP | 6000k |

| LIFESPAN | 50,000hrs |

| LENS | Harden Optical PC |

| WEIGHT | 2.4kg |

| OPERATING TEMP | – 40 to 155 C |

| HOUSING MATERIAL | Aluminium Alloy with Polyester UV Powder Coat |

| DIMENSIONS EXCLUDING BRACKET | (W) 340mm x (D)85mm (H) 76mm |

WHAT’S IN THE BOX

- 1 x 14″ 120W Hyper Flood LED Light

- Male and Female Deutsch with Pigtail

- 3 Series Stainless Nuts & Bolts