Description

Stedi Number Plate Light Mounting Bracket

DESIGNED TO BE A WINNER.

While most think that LED Driving Lights are only catering for the 4×4 community out there, you might be surprised to find that this bracket breaks down that wall. This bracket is made for the everyday user, providing a convenient LED application, all in a sleek and clean design.

COMPATIBILITY OF THE HIGHEST ORDER.

Will fit almost all factory front bumpers sizing just a little wider than your license plate to maintain the factory feel to your vehicle.

LIGHT BAR READY.

The STEDI Number Plate bracket runs no shortage of compatibility to LED Light Bars & Driving Lights through our range, and acts as an ideal solution if you need to install Spot Light or a LED Light Bar but do not have a nudge bar or bull bar to mount to!

THE NITTY GRITTY.

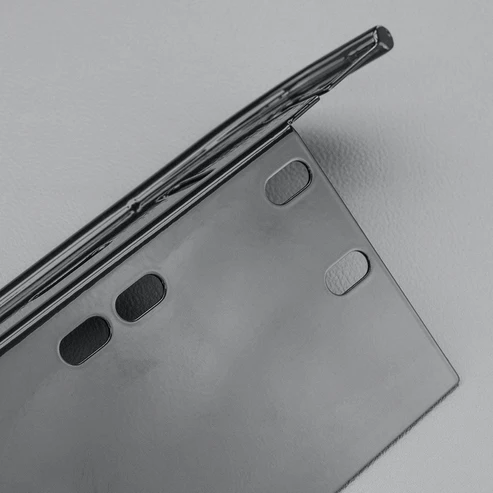

The STEDI Hardened Steel Number Plate light mounting brackets bolt through your existing number plate holes, for effortlessly mounting driving lights or and LED Light Bar.

Finished in a durable satin black UV stabilised powder coat, along with contoured tube section, makes for an aesthetically pleasing addition to any passenger vehicle.

Great solution if you need to install Spot Light or a LED Light Bar but do not have a nudge bar or bull bar to mount to. Universal fitment, with no modification required.

Fits most lights with adjustable bottom slide brackets.

Also has provision to mount UHF antenna.

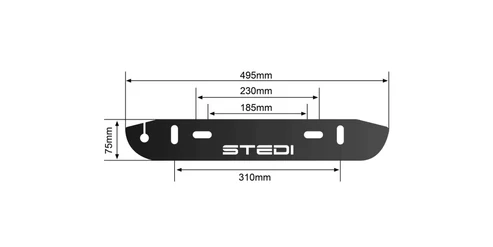

TECH SPECS

| MATERIAL | Hardened Steel |

| WEIGHT | 1.14Kg |

| FINISH |

UV rated Powder Coat

|